Our Objectives

We intended to

The Tyre Circular Economy

The circular economy of tyre recovery includes Import, Distribution, Consumption, Collection and Recycling.

As HK does not have a tyre manufacturing process, and there are constraints in exporting used tyre, the next feasible solution is to recycling the used tyre into usable products such as Steel Wire, Asphalt Additives, and as Alternative Fuel to recover its calorie value.

.png)

Our Complete Solution

Our complete solution starts from collection, processing and final recycling of waste tyre in order to provide a non-landfill solution with zero residual and secondary waste. The whole process is traceable, complies with all applicable governing laws and independent of export constraints.

The waste tyre collected will be processed into rubber powder suitable for used as alternative fuel in the cement kiln process to recover its heat value. The steel wire will be recovered and sell to steel recycler.

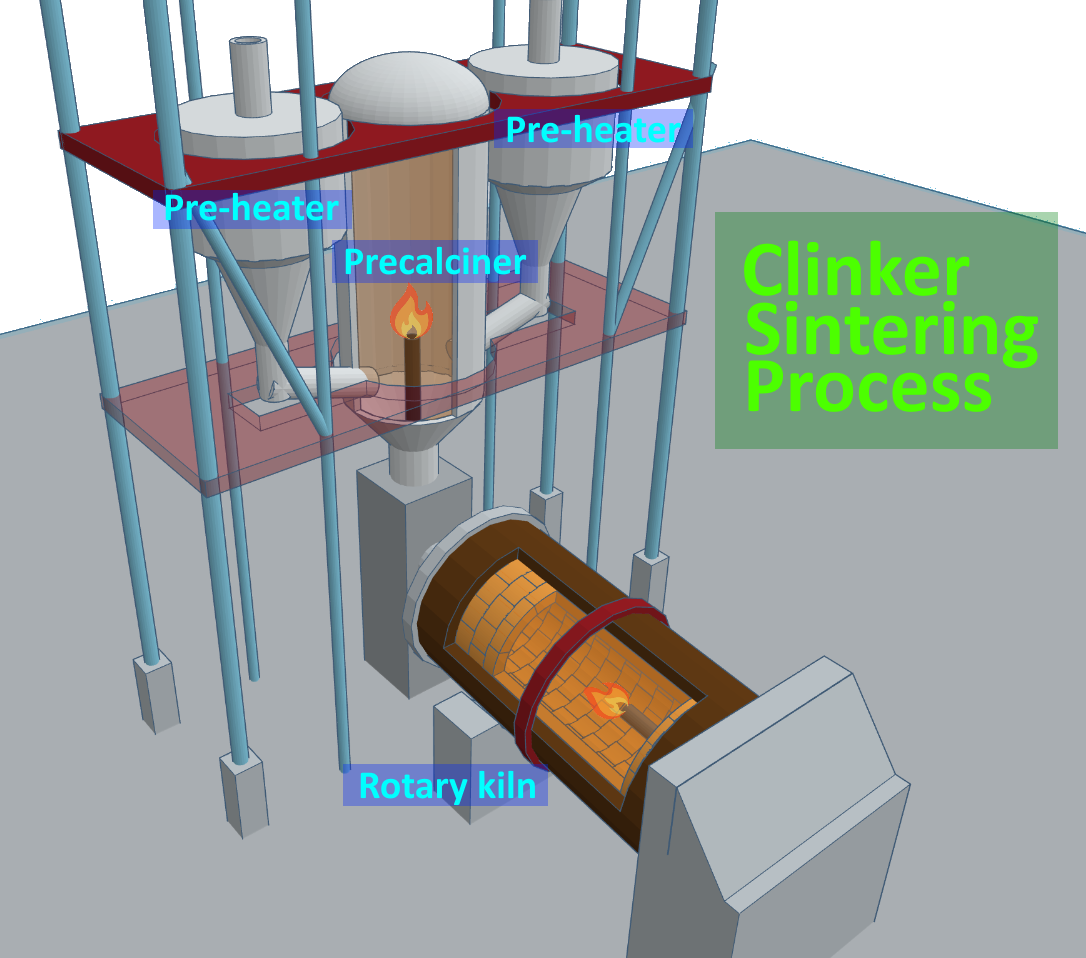

Clinker Sintering Process

In our cement manufacturing process, raw meal will be heated up from 50°c to 1000°c at the pre-heater, and then further increase the temperature to 1450°c at the burning zone of the kiln.

In the clinker sintering process, calorie value of waste is recovered to replace fossil fuel used in the two burners inside the precalciner & kiln. Rubber Derived Fuel can replace the amount of typical coal consumption as alternative fuel in our process.

The mineral ash of the RDF is combined into the clinker matrix and hence no residue nor secondary waste is left. The use of RDF as alternative fuel in the process can replace the amount of coal consumed as well as reduce the NOx emission.